X-treme QUAKE

Breaking the mould of conventional P&A

About the QUAKE

We’re breaking the mould of conventional P&A – introducing

X-treme QUAKE, the rapid acting cement and solids buster.

With QUAKE, we’re responding to industry’s call for new technology to dramatically reduce plugging and abandonment costs where operators have a duty to undertake environmentally responsible decommissioning of wells.

Typically, the task of removing casing induces operational risk, introducing scope growth and significant cost escalation.

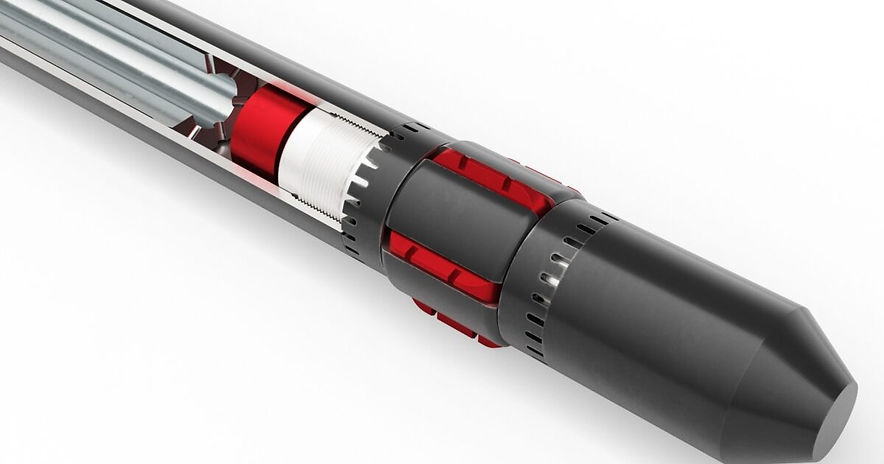

The QUAKE, powered by our proven INFINITY engine, uses a powerful radial striker system to deliver rapid, intense hammer blows inside the casing bore that transmit high frequency shock waves through the casing wall to break down cement or solids present in the casing annuli.

This differentiated technology provides a reduction in binding force to promote a simpler and safer casing recovery, enabling significant time savings and limiting unplanned events.

Simple in design with unique operational capability, operators can plan their well abandonment operations with confidence.

Features and benefits

-

Frees casing for rapid and safe extraction

-

Unimaginable bond breaking power

-

Instant and rapid activation

-

Low-pressure operation

-

Ultra-low-torque requirement

-

No slack-off or overpull force needed

-

Fast and effective

-

Shatters cement

-

Breaks cement and solid bonds

-

Mobilises settled barites and solids

-

Pre-treats annuli for optimised perf-wash-cement operations

-

Reduces operational time

-

Increases operational success

Technical details

Premium Connection Sub

X-treme QUAKE® can be dressed with any standard or premium threaded connection, removing the need for cross-overs.

.jpg)

Fluted Non-relating Sleeve

The Fluted Non-rotating sleeve provides lateral stability to the HAMMER whilst also indexing the percussion valve system.

HydroVolve INFINTY® Valve Module

The HydroVolve INFINITY® Valve module directs and commands the fluid power required to generate the percussive impact. HydroVolve INFINITY® uses string rotation to open and close the inlet and exhaust valves to allow pressurised fluid within the drill string to propel the percussive HAMMER mass.

Piston

The Piston provides the motive force to the HAMMER to generate acceleration for impact.

HAMMER

The HAMMER is the simple robust mass that is accelerated by the piston to strike the anvil to generate the impulse.

Anvil

The Anvil provides the point of impact for the HAMMER and transmits the impulse energy directly into the radial strikers.

Radial Strikers

The radial strikers are the impulse delivery components that transmit the radial impulse force to the wellbore to clean, agitate, and disrupt unwanted debris, solids and cement within the well.